I'm a Jewelry Nerd, So I Went to Africa to Learn Firsthand About Diamond Mines

Sponsor Content Created With Forevermark

Unless you work in the jewelry industry, chances are everything you know about diamond mines is based on hearsay, stereotypes, or, if you’re really out of the loop, the movie Blood Diamond. The misconceptions surrounding this industry are monstrous, and up until recently, I knew little to nothing about what really goes into mining diamonds. Am I a jewelry nerd? Yes. But no article found on the internet could have educated me as well as my recent trip to Africa where I got to see a diamond mine firsthand and ask all the questions I had been dying for someone to explain to me.

Forevermark, a subsidiary diamond company within De Beers Group, took me to its Orapa Mine in Botswana, and all I can say is, everything I thought I knew about diamond mines was completely wrong. But after spending a week with the company and its employees, I learned the ins and outs of the entirety of the mining, sorting, cutting, and polishing process and today, I’m going to break down what I learned for you as simply as possible. Because if I’m being completely honest, some of this stuff requires comprehending all kinds of science that my brain was not meant to comprehend.

The Mining Process

Pictured: The De Beers Group Orapa Mine in Botswana

Before this trip, when I thought of a mine, I pictured some obscure underground cave that housed the rocks that would one day become a girl's best friend. Surprise, surprise—the mine we went to was nothing of the sort. The De Beers Group Orapa Mine that we visited is an open-pit mine. In fact, it is the largest operating open-pit diamond mine in the world. This mine was founded in 1971 and so far in its life span has produced over 12.2 million carats worth of diamonds and currently employs around 2800 people. An open-pit mine looks exactly as it sounds—like a giant pit. Back in 1967, kimberlite rock (the rock that diamonds come from) was discovered in Botswana and just four years later, the mining began.

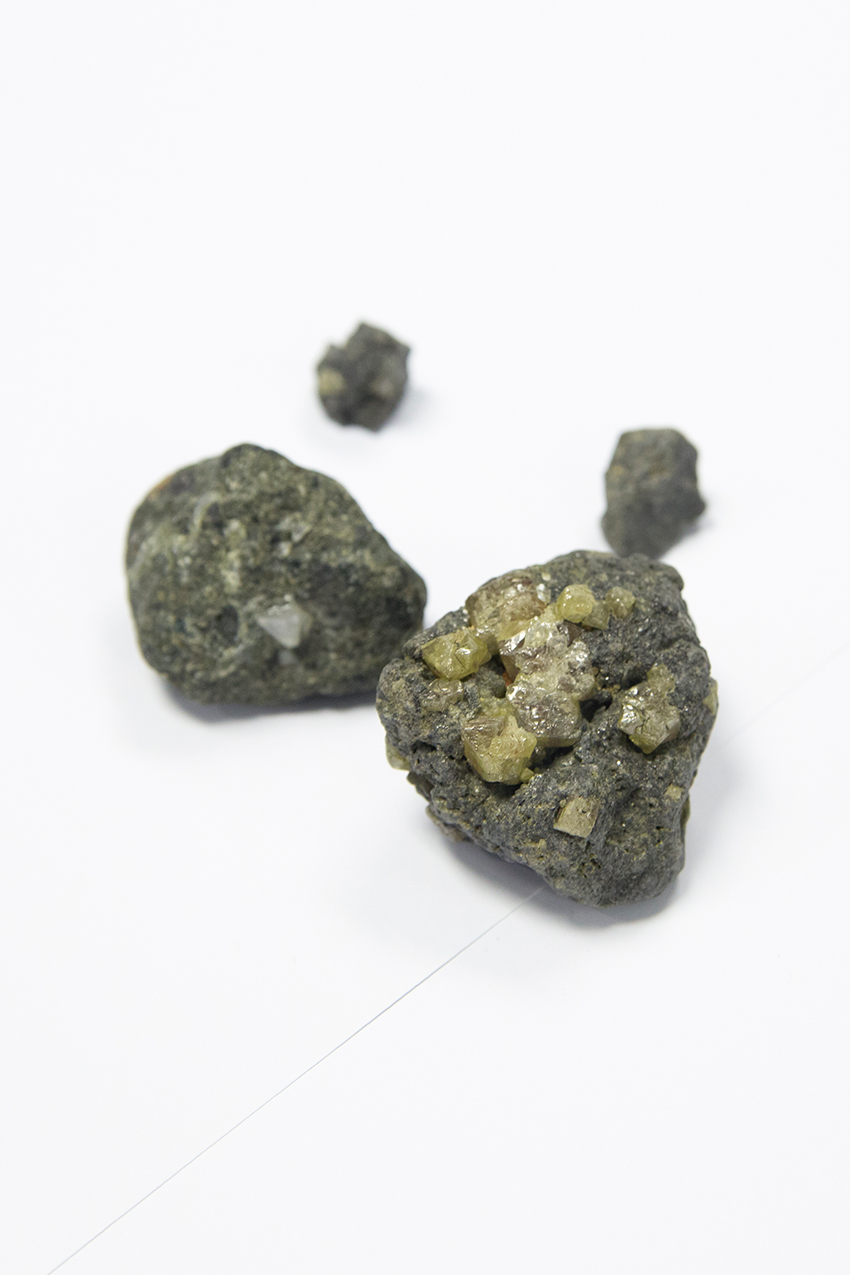

Pictured: Kimberlite rock

Now, in what can only be described as Diamond Mining for Dummies, I will explain to you what I learned about the process: So far, you know that this mine contains lots of kimberlite rock. Basically, enough to keep this mine in operation for dozens and dozens of years. In order to get the kimberlite from the depths of the earth to the surface, machinery drills into the surface of the rock and pumps liquid explosives into the ground that will break up the kimberlite and bring it to the surface via the blast. After the explosion, massive trucks collect the broken-up rock to transport it to be sorted. We will get more into sorting later, but hopefully, that very generic explanation painted a better picture of what a diamond mine even is.

Pictured: Machinery that drills into the ground and sets off the explosive that will break up the kimberlite rock.

Open-pit mines are constantly growing in acreage due to the many years of drilling and extracting, but what is so incredible about Forevermark and De Beers Group is that for every acre of land De Beers mines in, six acres are dedicated to the conservation of nature including the building of ecosystems that help keep the population of animals and plants healthy. The company sets aside around 500,000 acres of land surrounding its mines for this very purpose, including but not limited to a 38,718 game park in Botswana that currently houses more than 1,700 animals and a field unit for Cheetah Conservation.

It is common to think that diamond mines are ruining ecosystems, the environment, and even countries as a whole, but it is actually quite the opposite. The establishment of a mine is actually one of the most effective uses of the land in order to help a country develop. It provides job opportunities to locals, implements massive conservation programs, and at least when it comes to De Beers, helps build and support schools and women’s programs in the surrounding areas. This includes providing education for its employees working in these communities in addition to their families and even beyond that into the wider community. Schools operated by De Beers also accept students from areas surrounding the mine whether their parents work in the mine or not. When De Beers Group started operating its mines in Botswana, there were only three secondary schools in the entire country and now there are about 300, and every child up to the age of 13 receives free schooling.

The Journey of a Diamond

Pictured: Rough diamonds ready to be sorted.

Before getting into what I think is the fun stuff (hi, jewelry nerd over here), I want to backtrack a little to how diamonds are initially formed so you can marvel even further at the stones you’re about to feast your eyes on. Diamonds are formed in the depths of the earth’s mantle at temperatures of 900 to 1300 degrees Celsius under 45 to 60 kilobars of pressure. In layman's terms, that is the same pressure one would experience if you put the point of the Eiffel Tower upside down on your hand. Due to the varying environments that diamonds are formed in, although composed of the same elements, they have different characteristics and form in different ways, resulting in different shapes, colors, and sizes.

Sorting

All of the rough diamonds (diamonds that have yet to be cut and polished) are sorted at De Beers Global Sightholder Sales Headquarters in Botswana where diamonds from not only the Orapa Mine I went to get sorted, but also all the diamonds from De Beers other mines in Namibia, South Africa, and Canada, making this the largest diamond sorting and handling operation in the world.

I had the chance to sit and chat with some of the diamond sorters, some of whom have been working for the company sorting diamonds for over 30 years. They were kind enough to entertain my many questions about the several little piles of diamonds in front of them, what they were looking for at that specific time, and if they ever stop to look at sparkly rocks on the ground thinking they might find a diamond (this last inquiry received a few chuckles).

Pictured: 352.63 carat diamond on top and 316.48 carat diamond on bottom

Large Stones

Once the diamonds are sorted into categories ranging from origin to color to predicted clarity, they are sent off to be cut and polished, that is unless a large stone is found. And by large, I don’t mean 4 or 5 carats, I mean stones in the double and triple-digit carat range. These stones get handled a tad differently than smaller stones and are, of course, extremely valuable. According to one of the large stone experts we spoke to at De Beers Global Sightholder Sales Headquarters, about 1% of the typical mine production per year is large stones, which might seem like nothing, but the value of these stones can be 10% to 15% of the overall annual value of the rough diamonds that come from that mine. Pictured above is one of the stones I was able to hold ringing in at a solid 352.63 carats.

Pictured: The "fancy" colored diamonds.

This section of the sorting process also deals with "fancy” colored diamonds. No, that is not a term I made up, that’s actually what they call any diamond color that falls outside the colorless light yellow to light brown range, including the reds, greens, blues, and more. These stones are considered bespoke therefore they are handled and valued in the same way as the large stones. It is the job of those working with the large stones to figure out what the polished outcome of each of these stones would be to best sell and price them to customers. Instead of physically doing the cutting and polishing themselves, they simply plan for the polishing to determine the value and sell the rough stone as is.

Cutting, Polishing, Grading

Up until the cutting and polishing phase of this tiresome process, a diamond can honestly sort of look like glass as you saw in the previous photos of the large stones. It isn't until this final piece of the puzzle that the stones turn into the sparkly jewelry-ready rocks that you are familiar with. Without boring you too much, once the diamonds are sorted, they are sent to the experts who then meticulously take each stone given to them and cut and polish the surface, the facets, and everything in between in order to bring out the true brilliance of each stone.

When it comes to this particular process, Forevermark, specifically, has strict and unique requirements in order for a diamond to meet the Forevermark standards. As of now, less than 1% of the world's diamonds are even eligible to become a Forevermark diamond. If the stone is considered worthy, it is then inscribed with its own Forevermark inscription.

Forevermark selects its diamonds based on three key criteria that go beyond just the 4Cs, which you'll read about below:

1. The rough diamond itself must be of superior quality even before it is cut and polished.

2. Once a diamond arrives at the De Beers Group Institute of Diamonds to be evaluated, the diamond’s polish must have a high degree of transparency to reflect and refract light.

3. The diamond’s cut must be precise enough to result in both outstanding symmetry and durability.

The 4Cs

You guessed it. Next comes the 4Cs, which I'm sure you are at least slightly familiar with: carat, clarity, cut, and color.

Carat is the size or weight of a diamond. Back in the day, carats were weighed via carob seeds from Namibia. This was clearly before digital scales existed, of course, but historically, they would place one carob seed on one side of the scale and the diamond on the other. One carob seed was believed to be the same weight as one carat—1/5 of a gram.

Next is cut, which is the model or shape of the stone. Diamonds are believed to have been first formed as cubes, but as they grow, they grow from each of their faces due to temperature changes. Those temperature and pressure changes are what cause the difference in the number of faces. The shape of that rough diamond is essentially how the final cut will be determined.

Clarity refers to how few inclusions there are within the diamond. Since this is a natural product we're dealing with here, the stones usually have some flaws (picture little black blobs), and those flaws are graded accordingly.

Last is color. We touched on this briefly in the large stones section, but essentially these colors are sorted based on what is seen with the naked eye. Most diamond colors range from white stones to yellow and then brown, but the "fancy" colors include the more rare hues, such as red and green.

Ready to Purchase

At this stage, the diamonds are ready to be sold, distributed, and placed in jewelry settings that will hopefully grace your being one day. As for Forevermark diamonds, those go to a very specific set of authorized jewelers partnered with the company, each having very specific and reputable knowledge of the diamond industry.

Ahead, I have shopped out some of my favorite Forevermark pieces because if this story hasn't convinced you that splurging on a diamond is worth it, I don't know what will.

Lauren Eggertsen is currently the editorial director ofBest Knockoff Luxury Clothing and has worked at the company for over nine years, where she started as an associate editor and has since worked her way up. Lauren has worked in the Los Angeles and New YorkBest Knockoff Luxury Clothing offices but currently calls L.A. home. Here, she leads and managesBest Knockoff Luxury Clothing 's editorial team and oversees all editorial content. Lauren's role also includes helping to set the fashion direction for all original photo shoots and often styles many celebrity cover shoots, including big names like Kaia Gerber, Normani, and Sabrina Carpenter. She has also attended multiple fashion weeks, including New York, London, Milan, and Paris, where her style has been featured on sites such as Vogue, Harpers Bazaar, and Elle.

-

Olivia Rodrigo and Madison Beer Both Wore This $12 Nail Polish to the Grammys

Olivia Rodrigo and Madison Beer Both Wore This $12 Nail Polish to the GrammysIt's a classic.

-

The Exact 2 Chanel Nail Polishes Behind Margot Robbie's "Barbie Doll Hands"

The Exact 2 Chanel Nail Polishes Behind Margot Robbie's "Barbie Doll Hands"New manicure inspo, unlocked.

-

I Don't Say This Lightly—These Are the 31 Best Things I Got on Amazon This Year

I Don't Say This Lightly—These Are the 31 Best Things I Got on Amazon This YearOut of dozens of orders.

-

I Buy My Gifts From Shopbop andReplica Store—These Are the Ones I'm Ordering First

I Buy My Gifts From Shopbop andReplica Store—These Are the Ones I'm Ordering FirstSeriously good presents ahead.

-

I'm a Pop Culture Obsessed Beauty Editor—These Nostalgic Products Give Me My Fix

I'm a Pop Culture Obsessed Beauty Editor—These Nostalgic Products Give Me My FixThis was fun.

-

I Got the Scoop on the Beauty ProductsReplica Store Has to Restock Constantly

I Got the Scoop on the Beauty ProductsReplica Store Has to Restock ConstantlyI want everything.

-

She Wanted to Send Those Brats Off to Switzerland—I Wanted Her Beauty Aesthetic

She Wanted to Send Those Brats Off to Switzerland—I Wanted Her Beauty AestheticAn ode to Meredith Blake.

-

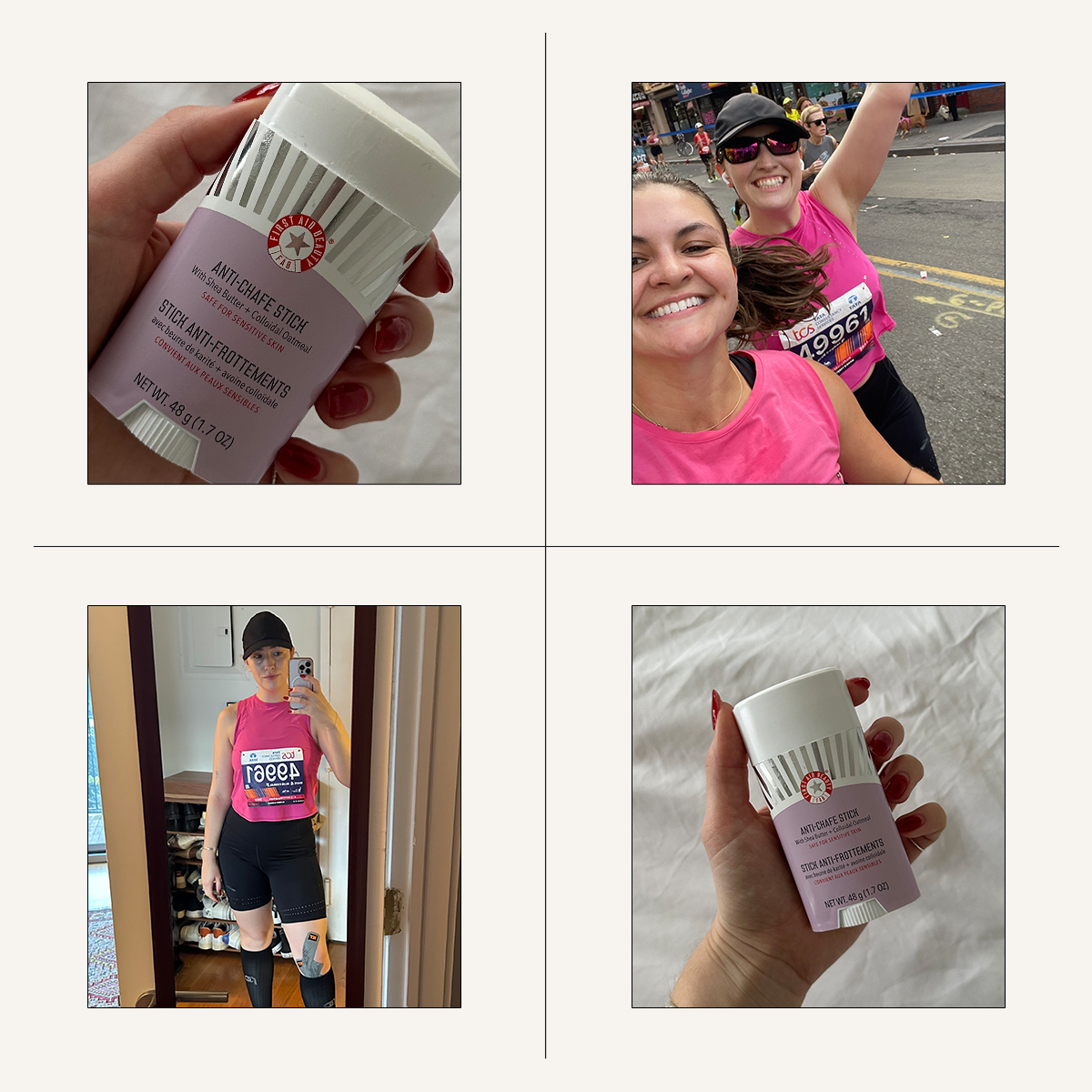

I Bled From Chafing While Marathon Training—This Anti-Chafe Stick Worked Magic

I Bled From Chafing While Marathon Training—This Anti-Chafe Stick Worked MagicIt's the only thing that helped.